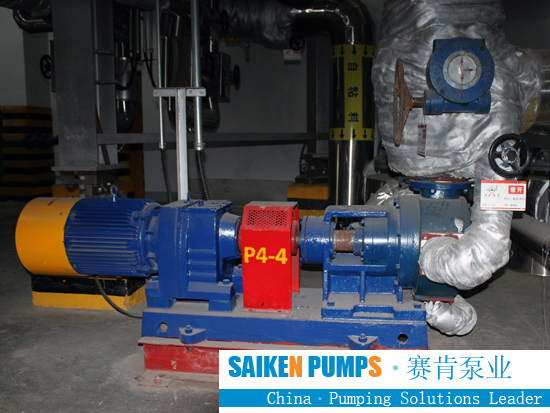

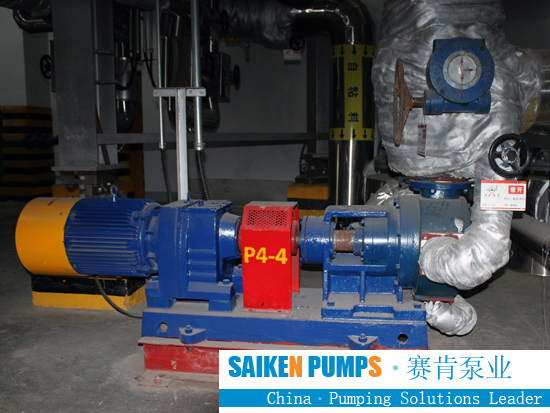

Polyurethane composite materials are commonly known as PU materials, foam materials, composite materials, black materials, white materials, and black oil and butter. They are used for building insulation, solar energy, water heaters, cold storage, constant temperature storage, beer tanks, cold storage and other occasions that require heat preservation and cold preservation. The medium has a high viscosity, so it is not feasible to use a conventional SS gear oil pump to transport polyurethane composite materials. The material is exhausted and the motor heats up seriously, which is easy to burn the motor. The high-viscosity gear pump produced by sai ken pump industry is a process pump specially designed to deal with some high-viscosity industries such as polyurethane, resin, and asphalt mixture. It has a very outstanding effect on the transportation of high-viscosity media.

The polyurethane composition solidifies and crystallizes when exposed to air. For the residual crystalline medium in the pump, the high-viscosity gear pump can be heated by heat-conducting oil or steam through the insulation jacket, and then can be adjusted by adjusting the rotor gap when the viscosity is too high. The maximum pressure can reach 1.0MPa. Sai ken pump industry has designed and developed a SS magnetic drive high viscosity pump for non-leakage and high-viscosity media. The magnetic drive high-viscosity pump adopts a permanent magnetic material seal, which is safe and leak-free. It is the first choice for the polyurethane composite industry.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501