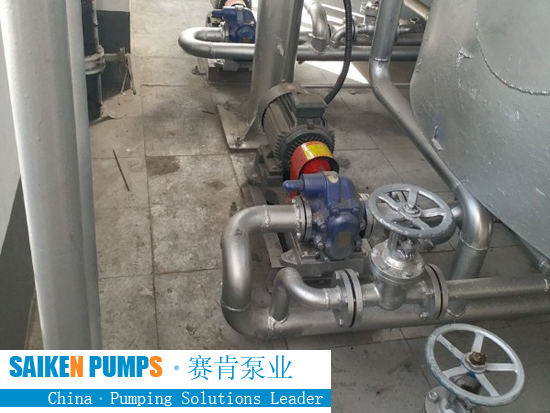

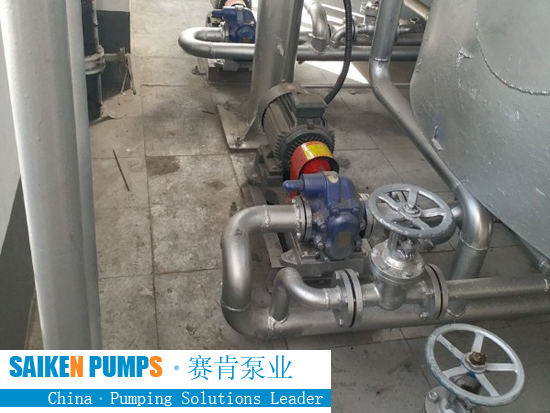

After the stainless steel gear pump is used, if the surface or inner cavity of the SS gear pump is repaired again, it will be dirty. Many customers do not pay much attention to the cleaning work during the repair, which makes the SS gear oil pump unable to rotate after the repair, or the gear oil pump is pumped due to improper assembly Not feeding.

When repairing the stainless steel gear pumps, the customer will damage the graphite gasket or the highland paper gasket between the original parts during the disassembly and assembly process, and replace it with plain paper during assembly, and pay little attention to the thickness of the original gasket. This causes two situations when the stainless steel gear pump is installed. One is that the gasket is thicker than the original one, which causes the internal end face clearance of the stainless steel gear pump. The gear pump cannot form a vacuum during operation, and the gear pump cannot suck at all. 上Media. The solution is to replace the gasket with the same thickness as the original. Another is that the gasket is too thin, and the stainless steel gear pump can't be rotated after assembly, so you need to replace a slightly thicker gasket for assembly. .

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501