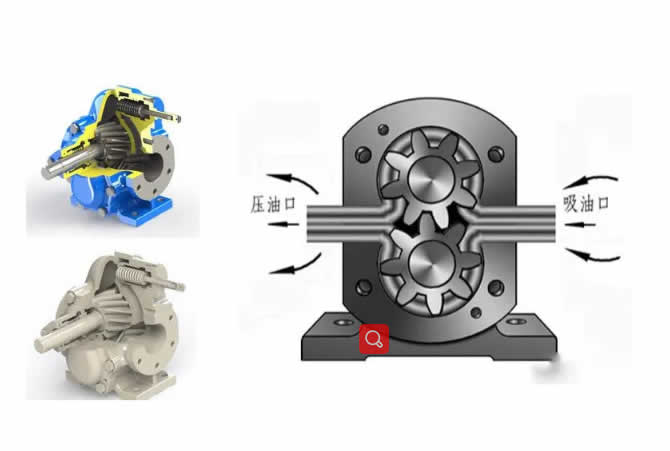

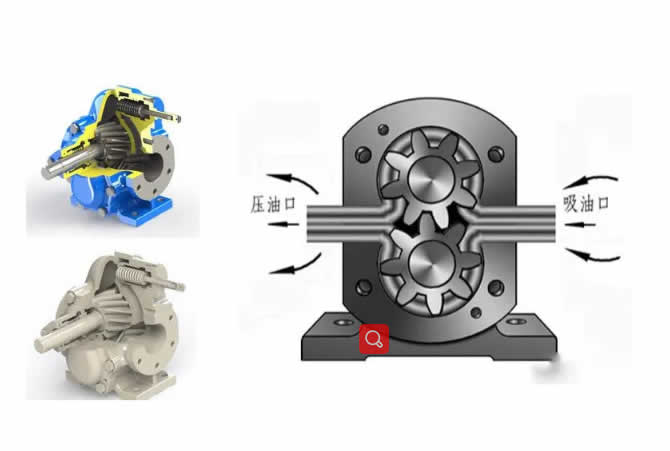

The concept of gear pump is very simple, that is, its most basic form is that two gears with the same size mesh and rotate in a closely matched housing. The inside of the housing is similar to an "8" shape. Two gears are installed inside. The outer diameter and both sides of the gear are closely matched with the housing. The materials from the extruder enter the middle of the two gears at the suction port and fill this space. They move along the shell with the rotation of the teeth and are discharged when the two teeth mesh.

In terms, gear pump is also called positive displacement device, that is, like a piston in a cylinder barrel, when one tooth enters the fluid space of another tooth, the liquid will be mechanically squeezed out. Because the liquid is incompressible, the liquid and the tooth cannot occupy the same space at the same time, so the liquid is eliminated. Because of the continuous engagement of the teeth, this phenomenon occurs continuously, which also provides a continuous discharge amount at the pump outlet. Every time the pump rotates, the discharge amount is the same. With the continuous rotation of the drive shaft, the pump will continuously discharge the fluid. The flow of the pump is directly related to the speed of the pump.

In fact, there is a small amount of fluid loss in the pump, which makes the operating efficiency of the pump unable to reach 100%. Because these fluids are used to lubricate both sides of the bearing and gear, and the pump body can never fit without clearance, so the fluid cannot be discharged 100% from the outlet, so a small amount of fluid loss is inevitable. However, the pump can still operate well, and for most extruded materials, the efficiency can still reach 93%~98%.

For the fluid whose viscosity or density changes in the process, this kind of pump will not be affected too much. If there is a damper, such as a screen or a limiter on the discharge side, the pump will push the fluid through them. If the damper changes during operation, that is, if the filter screen becomes dirty and blocked, or the back pressure of the limiter rises, the pump will still maintain a constant flow until the mechanical limit of the weakest component in the device is reached (usually a torque limiter is installed).

The speed of a pump is actually limited, which mainly depends on the process fluid. If the oil is conveyed, the pump can rotate at a high speed, but when the fluid is a high viscosity polymer melt, this limit will be greatly reduced.

It is very important to push the high viscosity fluid into the two tooth space on the suction side. If this space is not filled, the pump cannot discharge accurate flow, so the PV value (pressure × Flow rate) is also another limiting factor and a process variable. Because of these limitations, the gear pump manufacturer will provide a series of products, namely different specifications and displacement (the amount of discharge per revolution). These pumps will be matched with the specific application process to optimize the system capacity and price.

The gear pump is driven by an independent motor, which can effectively block the upstream pressure fluctuation and flow fluctuation. The pressure pulsation at the outlet of the gear pump can be controlled within 1%. Using a gear pump in the extrusion production line can improve the flow output speed, reduce the shearing and residence time of materials in the extruder, reduce the extrusion temperature and pressure pulsation, and improve the productivity and product quality

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501