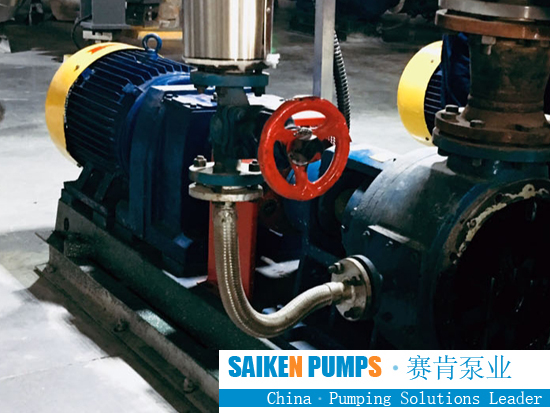

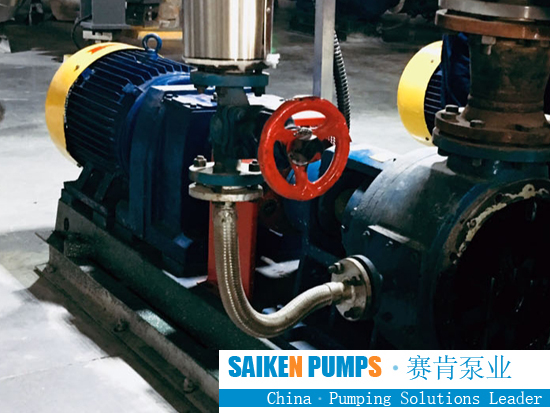

If there is a safety valve on the back cover of the insulated asphalt pump. The rear cover can be removed integrally with the safety valve; before removing the rear cover, a mark should be made to mark the relative position of the pump cover and the pump body, the bolts of the rear cover should be removed, and the rear cover should be removed. Note: When removing the back cover of the thermal insulation asphalt pump, the driven gear is usually connected to the gear shaft, and the back cover should be avoided to face down to prevent the driven gear from slipping and causing personal injury or gear damage. When there is no new gasket and the old gasket is not damaged, the old gasket can still be used. When installing, pay attention that the arrow on the valve body should be consistent with the flow direction of the medium. The stainless steelheat preservation asphalt pump cannot be installed in a place with direct dripping or splashing water. The insulated asphalt pump should be installed vertically upwards. The thermal heat preservation asphalt pump should be guaranteed to work normally within the 15%-10% fluctuation range of the rated voltage. After the heat preservation asphalt gear oil pump is installed, there must be no reverse pressure difference in the pipeline. It needs to be energized several times to make it suitable for temperature before it can be put into use. The pipeline should be thoroughly cleaned before installation of the SS heat preservation asphalt pump. The medium should be free of impurities. Install a filter before the valve. When the thermal heat preservation asphalt pump fails or is cleaned, a bypass device should be installed to ensure the system continues to operate.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501