Generally speaking, there are the following types of problems:

1. Overvoltage and excessive excitation current have the risk of breakdown.

2. The winding is grounded.

3. Short circuit of winding.

4. The winding is broken.

5. The winding lacks phase.

6. The motor is not grounded.

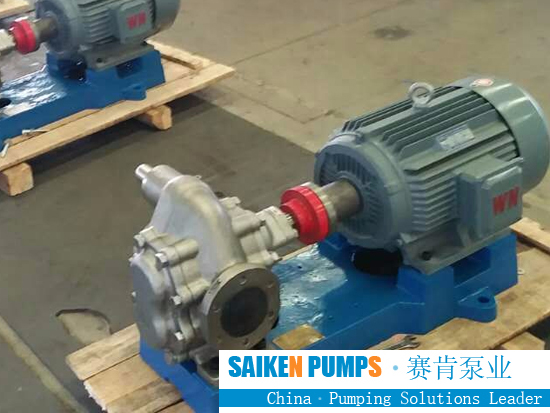

For us, the motor is one of the important equipment for the debugging of the stainless steel gear pump. To avoid burning the motor, in addition to taking the necessary protective measures before operation, the following six aspects are effective:

1. Ensure that the surface of the motor and the heat dissipation ribs are clean and hygienic, and ensure that the heat dissipation condition of the motor is good.

Second, strengthen the daily inspection of the motor and observe whether the motor has vibration, noise and odor. When the motor is running, especially for high-power motors, it is often necessary to check whether the anchor bolts, motor end cover, bearing gland, etc. are loose, and whether the grounding device is reliable.

3. The working current of the motor cannot be too large. During the debugging process, try to bring a motor with a gear up. As the motor is overloaded, the voltage is too low or the mechanical jamming caused by the motor will cause the motor to overload. Therefore, when the motor is running, it is necessary to always check whether the transmission device is flexible and reliable; whether the concentricity with the SS gear oil pump coupling is standard; the flexibility of the gear transmission, etc., if there is a stuck phenomenon, it should be stopped immediately to eliminate Run after the fault.

4. When doing the temperature rise experiment of the whole machine, pay attention to whether the temperature of the motor is too high. Always check whether the motor bearings are overheated or lack of oil. If the temperature rise near the bearings is too high, you should immediately shut down and check.

5. The three-phase current is unbalanced during the debugging process. After eliminating the abnormality of the inverter, determine the motor problem and stop the live work and apply for maintenance.

6. Regularly maintain and add lubricating oil to the SS gear oil pumps motor.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501