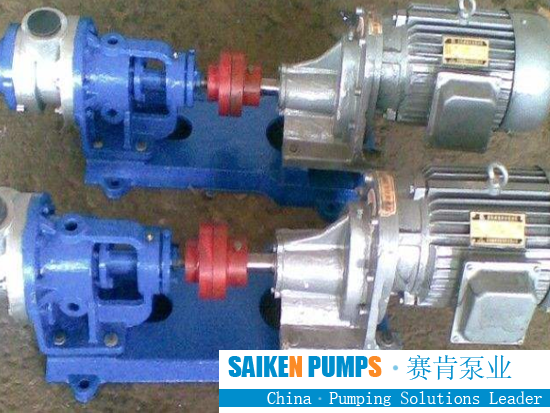

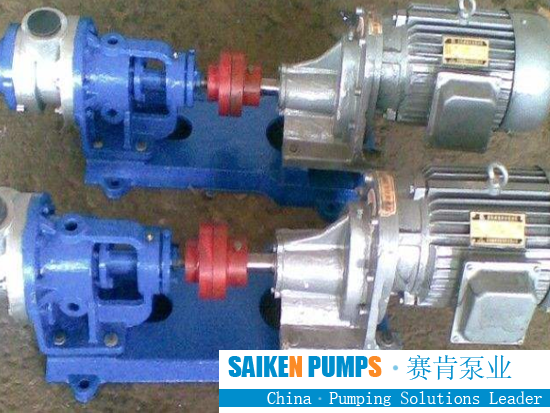

Stainless steel gear pumps need to be overhauled regularly. If the flow rate or pressure drops, the bearing sleeve is seriously worn and needs to be replaced. Check whether the meshing surface of the SS gear oil pump gear is worn, and the two ends of the gear are rubbed against the front cover or the back cover. The end surface of the gear can be smoothed and polished, and the gap can be readjusted during assembly. Gears are generally stressed on one side, and the gear can be turned on one side after grinding on one side. The thickness difference between the two gears should be within 0.005mm. If the gear is badly worn and cannot be repaired, the gear should be replaced.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501