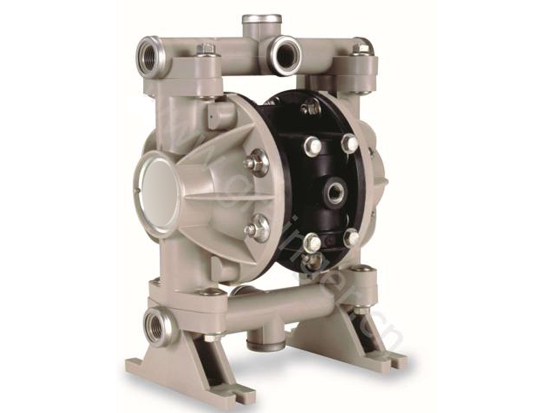

First of all, the plate filter press relies on the flow of the pump as its power. The flow is one of the important data for selecting the pump. The selection of the pump should be based on the processing volume and processing cycle of the equipment. Secondly, according to the volume of the filter chamber of the plate and frame filter press, the moisture content of the sludge after dehydration, and the concentration of the sludge before entering the plate and frame, the amount of sludge required for each completion of a dewatering operation is calculated. Then, determine a reasonable time to enter the mud, such as 2-3 hours. Calculate the flow rate. The material of pneumatic diaphragm pump is again: if it is ordinary biological sludge, it is more economical to choose ordinary cast iron or aluminum alloy. For other special sludge, pneumatic diaphragm pump materials such as engineering plastics, stainless steel 304 or 316L, and fully lined fluorine plastic diaphragm pumps should be selected according to the specific sludge composition. 1. Matters needing attention in design: 1. Install a pressure reducing valve and a small ball valve with pressure indication on the intake pipe to facilitate the observation and adjustment of the flow and pressure of the pneumatic diaphragm pump; 2, the air pressure should be controlled at the beginning of dehydration 2-3bar, when the water flow is significantly reduced, and then increase the air pressure, you will get a better dehydration effect; 3, the quality of the sludge conditioning effect, plays a decisive role; two, the shortcomings of the use of aodd pump : 1. The pressure cannot be increased and is limited by the air source pressure. 6bar reaches the upper limit; 2, noise and pipeline vibration are particularly obvious when the air volume is large; 3, compared to the screw pump, the diaphragm has a shorter life and is easily damaged; 4. Because the flow of Air operated double diaphragm pump is usually not too large, most of them are used in small systems; Three, the advantages of using pneumatic diaphragm pumps: 1. Low investment, screw pumps need to be able to adjust the flow device, frequency conversion or pressure adjustment valve, and A matching pressure sensor is required; 2, it is reliable and simple, and can automatically balance the flow as the filter resistance increases.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501