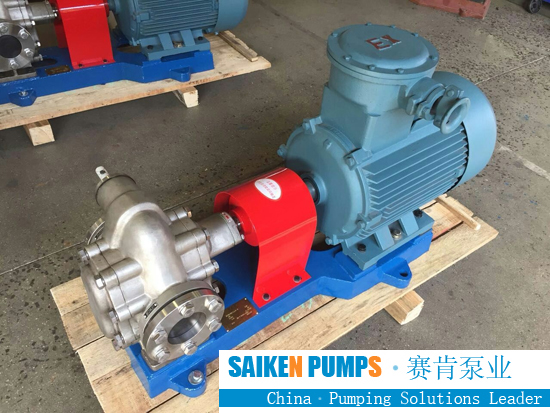

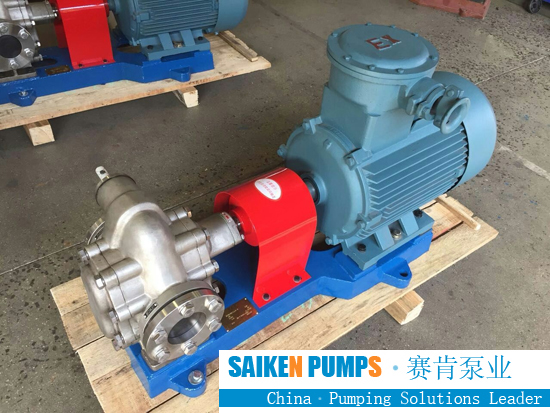

When installing the parts in the pump body of the KCB stainless steel gear pump, do not bring any debris and pollution. The parts must be cleaned with kerosene and coated with lubricant. When the upper and lower bearing seats of the KCB stainless steel gear pumps are assembled with the main and passive gears, the thickness difference between each pair of bearing seats and each pair of gears shall not be greater than 0.005mm. The gap between the two sides of the gears of the KCB stainless steel gear oil pump should be adjusted with paper pads. If the gap is too large, it will be easy to leak back, which will reduce the efficiency. KCB stainless steel gear pumps must be handled with care when assembling flexible graphite seals. It is strictly forbidden to throw or throw at random to prevent cracking or deformation. After the assembly of the SS KCB gear oil pumps is completed, turn the driving gear back to check whether there is a stuck point, and it should be flexible to rotate without blocking.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501