here are the following points: 1. In principle, the high viscosity rotor pump can only be based on the pressure, flow rate, viscosity, temperature, PH value, solid content, which are based on the selection and ordering...

There are the following:

1. In principle, the high-viscosity rotor pump can only be operated under the conditions of pressure, flow, viscosity, temperature, PH value, solid content, etc., which are based on the selection and ordering, as far as possible, to avoid operating in working conditions that exceed the limit conditions .

2. When the viscosity of SS High viscosity gear pumpis working, the increase of material viscosity, flow rate and pressure may easily cause overload of the motor. Always check whether the pressure gauge, valve and overcurrent protection device are normal.

3. There is a equipped with a thermal insulation device. It should be preheated by hot water (steam) before starting, and it will start after the pump temperature rises to the requirements of the conveying process. The pump should be stopped before shutting down the hot water (steam) before shutting down.

4. Equipped with a mechanical sealing device for cooling water, turn on the cooling water before starting the machine, and then turn on the High viscosity gear pump, and often observe whether the cooling water is normal. It is strictly forbidden to run without cooling water.

5. After installing the new pump, the filter and filter screen should be cleaned every month within one year to avoid blockage and cause the SS high viscosity rotor pump to not operate normally.

6. For the delivery of coagulating high-viscosity media, the medium in the should be diluted before stopping the pump to prevent the coagulation of the high-viscosity medium in the pump. If necessary, please use the cleaning solution and wash through the pump for 5-10 minutes.

7. Transport the medium that will thicken and condense after cooling. After the operation is completed, it should be run in cleaning fluid for 5-10 minutes in order to clean the inner cavity. If necessary, change the cleaning solution several times and extend the cleaning time.

8. For newly installed pipelines, the welding slag and hard particles in the pipeline must be removed to avoid entering the pump cavity and damaging the rotor, pump body, main and auxiliary shafts, mechanical seals, etc.

9. Regularly check whether the connections and tightening screws are loose. If so, please tighten them in time.

10. Always check the oil mirror of the gear box. If there is no oil surface, you need to add oil. The amount of oil should be half of the oil mirror.

展开

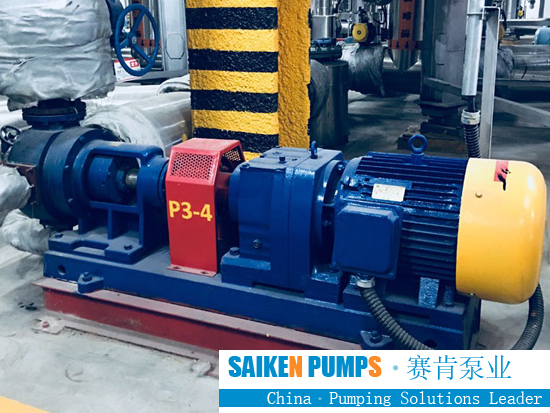

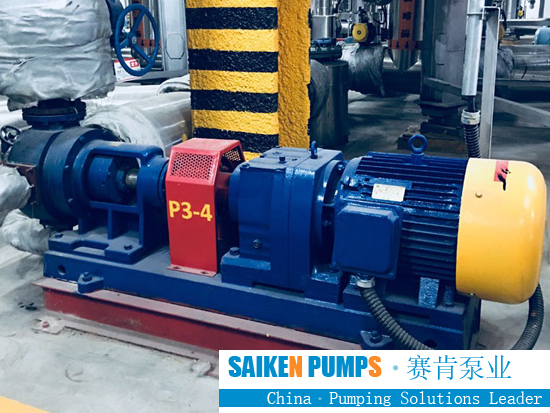

High viscosity gear pump

展开

High viscosity gear pump

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501