How do an rotary gear pumps work?

Internal rotary gear pump working principle

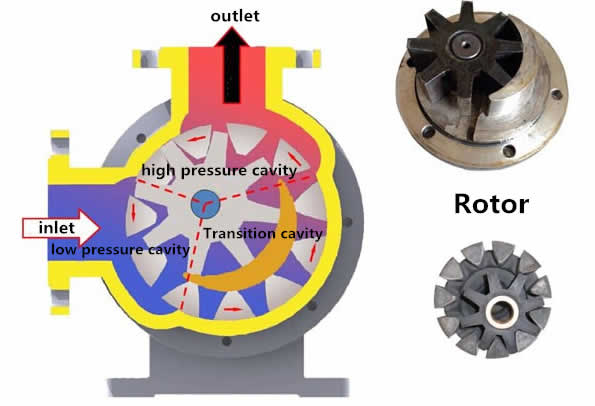

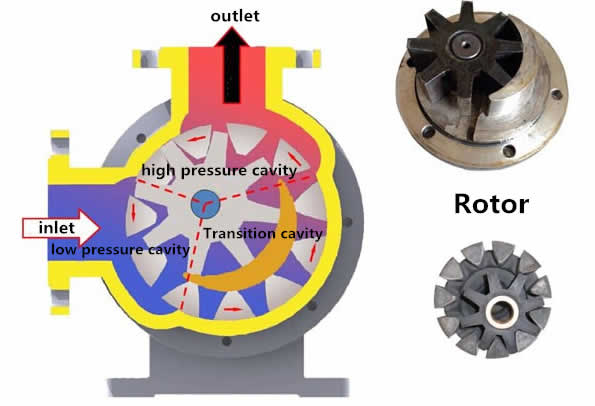

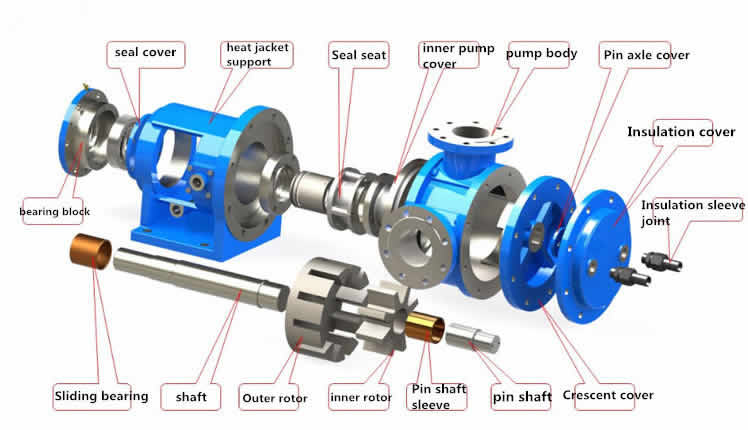

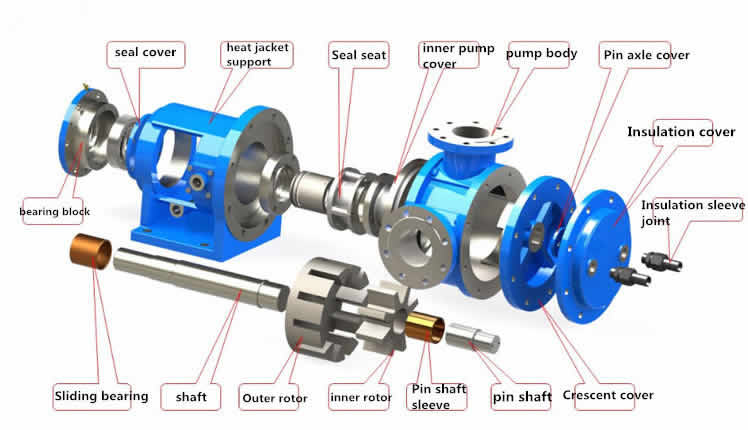

Internal rotary gear pump employs a positive displacement principle. The pump features a casing in which a dual gear (an outer rotor gear and an internal idler gear) and crescent assembly is housed. As the rotor gear begins to turn, the idler gear rotates with the teeth beginning to mesh accordingly. It is the space between these gears and the meshing action which both draws in the fluid and displaces it. The crescent shape both offsets the idler gear and provides a seal between the suction and discharge ports.

What applications and fluids is it suitable for?

Internal rotary gear pump is typically specified for viscous fluids such as oils, bitumen, fats, syrups, chocolate and resins as the more viscous the product is, the more efficient the displacement aspect of the working principle becomes. An internal rotary gear pump can handle fluids with a viscosity of 300,000cSt!

Internal rotary gear pump is typically specified for viscous fluids such as oils, bitumen, fats, syrups, chocolate and resins as the more viscous the product is, the more efficient the displacement aspect of the working principle becomes. An internal rotary gear pump can handle fluids with a viscosity of 300,000cSt!

The pump'seal adopts packing seal or mechanical seal.When the delivered medium is high temperatur ,high visc or strong corrosion,packing seal should be adopted. When the delivered medium is easy crystallinic ,we can designthe heat preservation jacket in pump casing and front cover in order to melt the medium with steam wen working.The pump can be also fitted with the safty valve. The pump set is composed of the pump,motor and baseplate. The driving way is belt wheel driving or coupling driwing.

The advantages of internal rotary gear pump - Smooth flow of high viscous fluids

The gear pump has many advantages due to the gear mechanism being finished with close tolerances providing a highly efficient performance in terms of suction and discharge. The nature of the gear teeth and powerful motion makes it exceptional at handling viscous fluids up to 100,000cps including chocolate, fats, glue, resin, oils and similar.

Although the pump does handle solids and abrasive material well, the pump can handle shear sensitive fluids with a gentle non-pulsating flow thanks to the cumulative, smooth delivery of the gear teeth meshing. The flow is directly proportional to the speed, independent of the pressure, giving much greater control and reliability to the service operator.

The advantages of an internal rotary gear pump - Outstanding engineering

Due to the shape of the gears and how they are assembled, the pump can handle high temperatures (approximately 250oC with some models even higher than this) and can handle high system pressures.

The pump can also be operated in both directions allowing the same pump to transfer in both directions. Due to the exceptional tolerances, the suction lift created by the gear mechanism is self-priming.

Applications for internal rotary gear pump

Typically an internal rotary gear pump excels at handling 'clean' viscous fluids. Gear pumps are also used commonly on lower viscosity fluids where a constant flow is required at high pressure such as feeding a burner system with diesel fuel.

Chocolates, fats and oils

Resins and polymers

Bitumen and tar

Fuel and lubricants

Solvents

Soap and personal care products

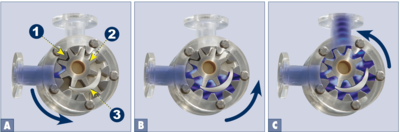

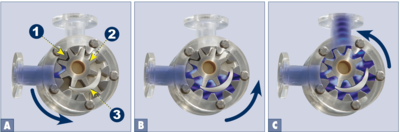

Fluid path and gear mechanism

On the picture on the right, you see the fluid path and gear mechanism. Two gears generate the flow - The rotor (1) and the idler (2). The rotor drives the internal idler. As the gears rotate, liquid is drawn into the spaces by the crescent (3) and smoothly transported towards the discharge port, where the gears mesh, closing the space and expelling the fluid. The result is a constant, smooth flow with no pulsation.

Our complete range of saiken internal Rotary Gear pumps include NYP0.78, NYP2.3, NYP7.0/3, NYP52/10, NYP80, NYP111/30, NYP160, NYP220, NYP320, NYP650, NYP727, nyp1670 and so on,

For more information, please visit : www.saikenpumps.com/INTERNAL-GEAR-PUMP/NYP-Internal-Gear-Pump.html

For more information, please visit : www.saikenpumps.com/INTERNAL-GEAR-PUMP/NYP-Internal-Gear-Pump.html

Saiken pump is NYP internal Rotary Gear pumps manufacturer & supplier and wholesaler in china, has many years of manufacturing experience, factory best price, If your have any requirements, please contact fan@saikenpumps.com .

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501