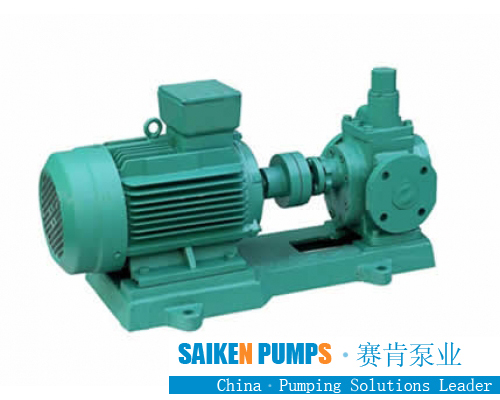

Saiken Pump Industry will introduce you the method of installing gear oil pump:

The installation of the gear pump must be carried out in accordance with the requirements in the product manual. The details and methods that should be paid attention to during the installation and use of gear oil pumps are summarized as follows:

1. When tightening the end face bolts of the gear oil pump, the gear pump should be symmetrically and evenly applied, and the rotor should be twisted tightly. In case of jam, the gear pump should loosen the bolts and tighten again;

2. The connection between the drive shaft of the electric pump and the motor shaft adopts an elastic coupling or a chain coupling;

3. The drive shaft of the gear oil pump cannot bear any radial vertical force, and the use of lateral drive methods such as belts, chains, and gears is prohibited;

4. The bottom plate must be strong enough, not for a long time. The bottom plate of the pump is soft, causing the motor and the pump to misalign and damage the pump;

5. Find out the maximum allowable speed of the pump and the maximum speed of the site work;

6. Be sure to let the fluid enter the inlet, try not to dry or idling;

7. Do not connect the inlet and outlet of the gear oil pump in reverse. Otherwise, the pump will not discharge

Gear pump manufacturers and suppliers from China

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501