Saiken Pump Industry will introduce to you the starting and stopping methods of gear pumps:

1, start:

(1) Check the tightness of all pipeline flanges and joints before starting.

(2) Rotating coupling, no friction and collision sound.

(3) The pump should be filled with delivery liquid when it is started for the first time.

(4) Fully open the valves in the suction and discharge pipelines before starting, and it is strictly forbidden to start with closed valves.

(5) After verifying the direction of motor rotation, start the motor.

2, parking:

(1) Turn off the motor.

(2) Close the inlet and outlet valves of the pump.

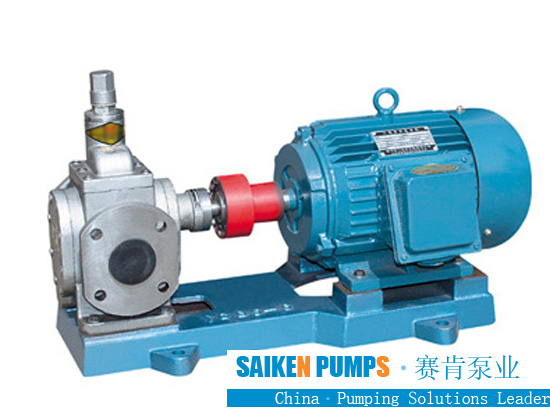

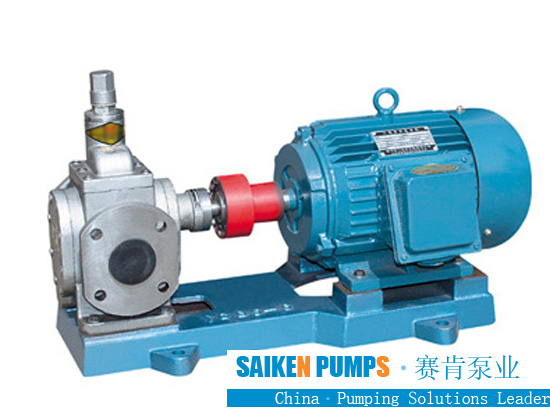

A pair of meshing gears and pump cylinders separate the suction chamber and the discharge chamber. When the gear rotates, the volume between the teeth where the gear teeth on the suction cavity side disengage from each other gradually increases, the pressure decreases, and the liquid enters the teeth under the action of the pressure difference. As the gear rotates, the liquid between the teeth is brought to the discharge chamber. At this time, the volume between the teeth of the gear teeth on the discharge cavity side gradually decreases, and the liquid is discharged. Gear pumps are suitable for transporting lubricating liquids that do not contain solid particles, are non-corrosive, and have a large viscosity range. The flow rate of the pump can reach 300m3/h, and the pressure can reach 3×107 Pa. It is usually used as a hydraulic pump and conveying various oil products. The gear pump has a simple and compact structure, easy manufacture, convenient maintenance, self-priming capability, but large flow and pressure pulsation and high noise. The gear pump must be equipped with a safety valve to prevent damage to the pump or prime mover due to some reasons such as blockage of the discharge pipe causing the pump outlet pressure to exceed the allowable value.

Gear pump manufacturers and suppliers from China

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501