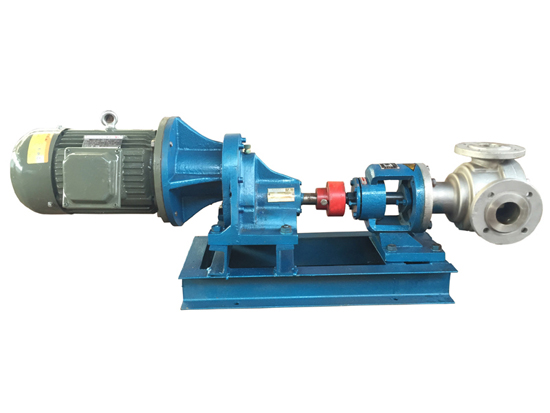

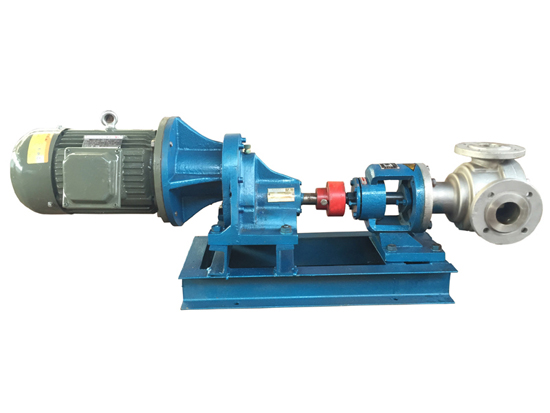

We're professional Heat Transfer Oil Pump manufacturers and suppliers in China high quality products with competitive price. We warmly welcome you to buy Hot oil circulating pump from our factory...

read more

1 inch GRACO diaphragm pump perfect replacement Air Operated Diaphragm Pump Model:SKQ-25ASTFF Max Capacity:150LPM, Max pressure:8.4Bar Material Body/Diaphragm/Valve ball/Valve seat: PP/Teflon/PTFE/PTFE Pump Inlet Outlet:1/1 (flange type), A...

2021-01-18