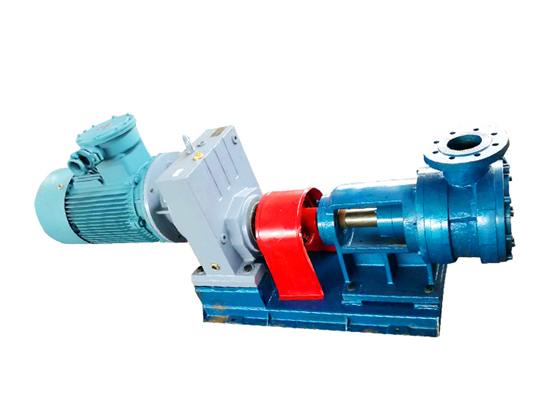

Advantages of high viscosity pump products:

1. High viscosity pumps are mainly composed of inner and outer rotors, shafts, pump bodies, pump covers, brackets, seals, bearings, etc.

2. The conveying liquid is stable, without pulsation, low vibration and low noise.

3. The speed of the high-viscosity pump has a linear function relationship with the flow rate, and the flow rate of the pump can be changed by changing the speed appropriately. High viscosity pumps are especially suitable for the transportation of high viscosity media. High viscosity pump shaft end adopts mechanical seal.

4. Maximum prevention of leakage. Suitable for outdoor installation, the fully enclosed magnetic coupling cavity can protect the outer magnet from moisture or external substances.

5. A variety of standard sliding bearing materials are available: cast iron, copper, graphite, tungsten carbide. The standard magnet material is NdFeB alloy. The optional samarium cobalt magnet allows the operating temperature to be as high as 250 degrees Celsius.

It can be transported in both directions.

The front cover and the external heating jacket of the magnetic coupling shield are standard optional parts.

Real back pull design.

Standard flange connection, only light pump head can be provided.

With inner jacket protection.

Patented cooling system: integrated cooling circulation system in the pump, without external cooling.

The dynamic axial balance system reduces the axial load, reduces power consumption and extends service life.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501