High-viscosity pumps include NYP high-viscosity internal gear pumps and rotary lobe pumps, which can be adapted to media of different viscosities by adjusting the rotational speed of the high-viscosity pump. Today we mainly introduce the NYP high viscosity internal gear pump!

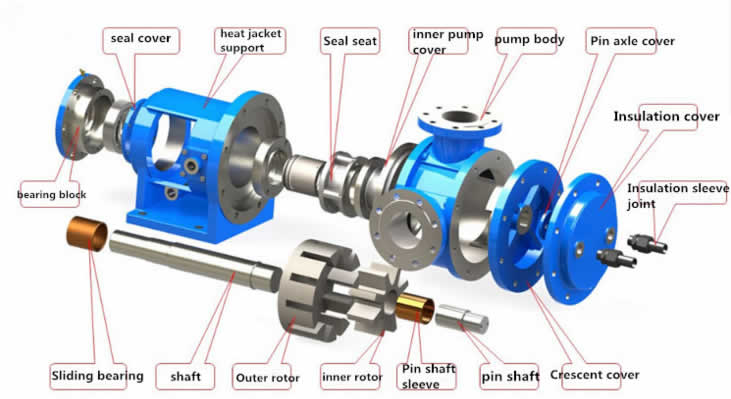

1. The structure of the high viscosity pump

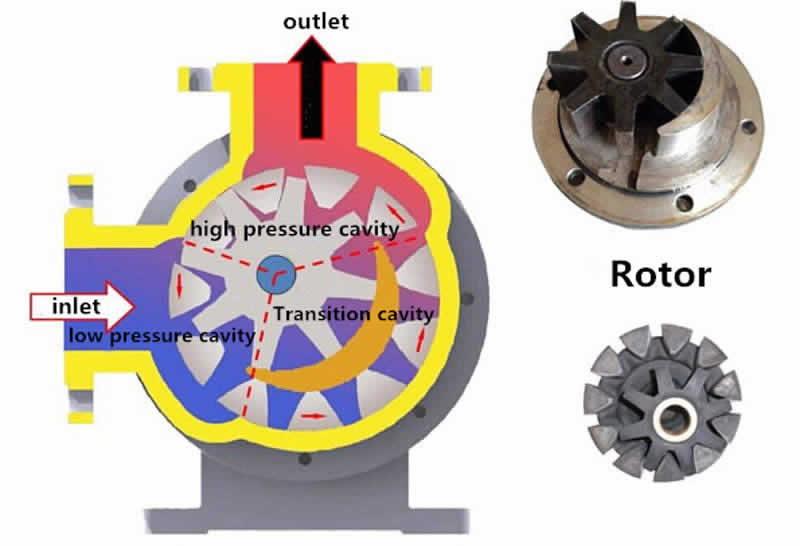

1. The high viscosity pump is mainly composed of inner rotor, outer rotor, shaft, pump body, front cover, bracket, seal, bearing, etc.;

2. There are two types of seals: mechanical seal and packing seal. For medium with high temperature, high viscosity and strong corrosiveness, packing seal is selected.

3. When conveying materials that are easy to crystallize, the pump body with thermal insulation jacket can be selected;

4. The pump can be equipped with a safety valve. When the pressure in the pipeline or pump body is too high, the safety valve will be opened to ensure the safety of the circuit.

Second, the advantages of high viscosity pump

1. Strong self-priming ability;

2. The conveying liquid is stable, without pulsation and with low noise;

3. The rotation of the inner and outer rotors is the same, the wear is small, and the service life is long;

4. Especially suitable for high viscosity medium;

3. Matters needing attention when choosing a pump

1. Comprehensively consider the physical and chemical properties of the medium;

2. The inlet pressure and outlet pressure of the pump and the installation height are very important for the selection;

3. Whether the use environment has explosion-proof requirements;

The high-viscosity pump has a simple structure and outstanding advantages, and is the first choice for various types of high-viscosity media.

If you need to know more, please email me: fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501