1. Diaphragm pump start-stop load operation:Air Diaphragm pump is driven by variable frequency motor. If the start-stop load is too large or too small, in order to avoid the above situation as much as possible, the start-stop load must be controlled at about 30%, and set in the instrument so that the load increase and decrease must be completed within a period of time, in order to effectively maintain the Look at the frequency converter from a technical point of view.

2. Operation of diaphragm pump instrument air and lubricating oil pressure system: diaphragm pump instrument air and lubricating oil pressure is interlocked with the main motor. The fuel injection and drain valves of the propellant are air-closed valves. They should always maintain a certain air pressure. The minimum working pressure of the two valves is not less than 0.4 MPa, so even after the pump is stopped, the instrument air pressure is generally maintained above 015 MPa. The air supplied to the valve is filtered and oil atomized to avoid insufficient or excessive liquid in the room. When the diaphragm pump is running, the lubricating oil pressure should not be lower than the pressure interlock value (0.15MPa), the pressure difference of the lubricating oil outlet filter should not be too large, the steel ball in the lubricating oil flow peeper should be at the upper limit position, and the adjustment range should be adjusted The flow rate should not be too large, so as to avoid the instantaneous flow rate being too fast and causing chain trips.

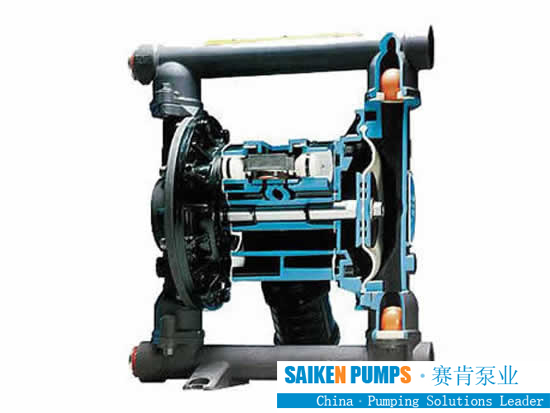

The flow characteristics of a diaphragm pump refers to the relationship between the relative flow of the medium through the valve and the displacement (relative opening of the valve). Ideal flow characteristics mainly include straight line, equal percentage (logarithm), parabola and quick opening. The characteristic curve and shape of the spool are shown in the figure. 1 and 2. Commonly used ideal flow characteristics are straight line, equal percentage (logarithmic) and quick opening.

The selection of the flow characteristics of the diaphragm pump can be calculated theoretically, but the methods and equations used are very complicated. Using empirical criteria to consider the following aspects: (1) the analysis and selection of the adjustment quality of the adjustment system; (2) the consideration of the process pipeline; (3) the analysis of load changes.

The shape and structure of the valve core can be determined by selecting the flow characteristics of the diaphragm pump, but for diaphragm valves and butterfly valves, due to their structural characteristics, it is not necessary to change the surface shape of the valve core to achieve the required flow characteristics. possible.

main comparison

High-pressure airless spraying is widely used in construction, machinery, shipbuilding, furniture and other industries due to its high efficiency, smooth surface, strong adhesion, and low paint damage. High-pressure airless sprayer is divided into pneumatic airless sprayer, electric airless sprayer (plunger pump) and electric airless sprayer (diaphragm pump). The use of pneumatic airless sprayers is limited by the demand for compressed air sources. Compare the electric plunger airless sprayer with the electric diaphragm airless sprayer. The plunger pump drives the plunger to reciprocate through a DC motor, sucks in paint, and discharges it after pressure. Because the plunger is exposed, it plays a certain role in the paint. Under the action of the coating grinding, the plunger wears quickly. Once equipped with a large diameter nozzle, the reciprocating frequency of the plunger increases, which intensifies the wear of the plunger. Wear and tear, the machine life is short. The replacement of the plunger is very expensive. If the voltage is abnormal, it will directly cause the abnormal operation of the direct current. In addition, due to the large reciprocating movement of the plunger pump, pulsation occurs during operation, which makes the injection unstable and the spray wall smoothness is insufficient. But the plunger pump has the advantage of fast initial suction. The diaphragm airless sprayer (diaphragm pump) is designed on the basis of the plunger pump. The principle is that the motor drives the piston to move back and forth (note that the piston does not directly touch the paint) to promote the movement of the diaphragm. After absorbing and pressurizing the paint, the coated object is sprayed through the nozzle. Since the piston works in wear-resistant oil, the working environment is very good.

Appropriate occasion

Due to the above-mentioned characteristics of pneumatic diaphragm pumps, diaphragm pumps have gradually entered the market of other pumps in the world since their birth, and occupy a part of them. For example, diaphragm pumps occupies an absolute dominant position in the paint and ceramic industries, while in other industries such as environmental protection, wastewater treatment, construction, sewage, and fine chemicals, diaphragm pumps are expanding their market share and occupy an irreplaceable position in other pump industries. The advantages of pneumatic diaphragm pumps are:

1. Since air is used as power, the flow rate is automatically adjusted with the change of back pressure (outlet resistance), which is suitable for medium and high viscosity fluids. The operating point of the centrifugal pump is set based on water. If it is used for a fluid with a slightly higher viscosity, it needs to be used with a reducer or a frequency converter governor, which greatly increases the cost and is also applicable.

2. The pneumatic pump has reliable performance and low cost in the transportation of fuel, gunpowder, explosives and other flammable and explosive environments. The reasons are: first, no sparks can be generated after grounding; second, there is no heat during work, and the machine will not overheat; third, diaphragm The pump has SMA so the fluid will not overheat. The biggest disturbance to the liquid.

3. In harsh places such as construction sites, industrial and mining wastewater discharge, etc., due to the large amount of impurities and complex components in the sewage, the pipeline is easily blocked, so the water pump will be overloaded and the motor will generate heat. The pneumatic diaphragm pump can be adjusted by particles and flow. When the pipeline is blocked, it will automatically stop until the pipeline is unblocked.

4. In addition, the diaphragm pump is small in size, easy to move, no foundation required, small footprint, convenient installation, and economical. Can be used as a mobile material transfer pump.

5. In the treatment of dangerous and corrosive substances, the diaphragm pump can completely separate the substances from the outside world.

6, or conduct some tests to ensure that no impurities contaminate the raw materials.

7. It can be used to transport fluids with unstable chemical properties, such as photosensitive materials, flocculants, etc., because the diaphragm pump has low shear force and small physical impact on the material.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501