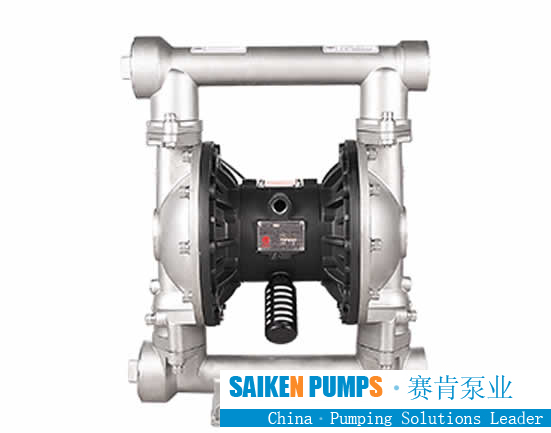

Internal diaphragm installation of diaphragm pump

The diaphragm pump equipment system is composed of one or more double-sided pumps, such as air double diaphragm pumps. The manifold on the pump is separated so that each side of the pump can pump out one component of the multi-component material, and an accumulator is connected with the outputs on both sides, so that the out-of-phase output of the pump becomes the same phase. Diaphragm isolation valves can be used on each side of the pump to prevent the mixed material from returning. If a mixing ratio other than 1:1 is required, more than one such pump can be used together to achieve a variety of mixing ratios.

The diaphragm failure monitoring system is used to detect the leakage of the diaphragm of the diaphragm pump. The system includes a pump, which has a working chamber with working fluid inside; a pumping chamber for pumping materials into and out of the pump; and a diaphragm to isolate the working chamber from the pumping chamber. A first optical fiber is connected to the working chamber for transmitting an optical signal through the working fluid. A second optical fiber is connected to the working chamber to receive the optical signal transmitted by the first optical fiber. An electrical signal establishment device that establishes the first electrical signal when the optical signal is transmitted from the first optical fiber and passes through the uncontaminated working fluid to the second optical fiber. This electrical signal establishing device establishes a second electrical signal when the optical signal is transmitted from the first optical fiber, passes through the contaminated working fluid and reaches the second optical fiber. When the second electrical signal is established, according to this, the leakage of contaminated material through the diaphragm into the working chamber can be detected.

2. The installation method of the internal diaphragm of the diaphragm pump is to make full use of the excellent pressure resistance of the diaphragm without affecting the volume change requirements of the pump. It is carried out on the geometric size of the diaphragm. It does not need to increase the cost and workload. It also greatly improves the service life of the diaphragm, guarantees the normalization of production and improves the quality of product production. It can be applied to the installation of diaphragms in various diaphragm pumps.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501