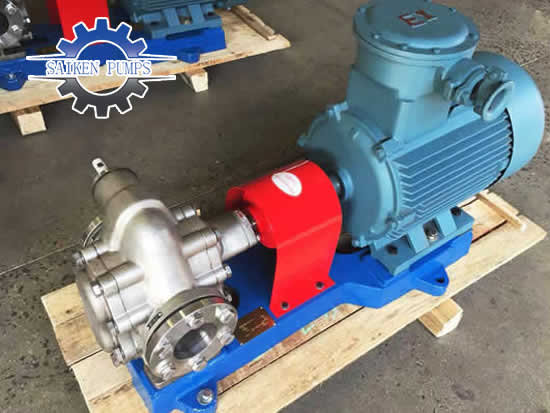

The stainless steel gear pump is suitable for conveying materials with a viscosity of 5-1500cst. What are the working conditions for ss gear pumps?

1. The reason why it is called a stainless steel gear pump is because the material is 304 or 316 or 316L corrosion-resistant material, which can transport acidic or alkaline or mixed materials. For example, the chemical industry, printing and dyeing machinery, marine engineering and other corrosive working conditions.

2. The stainless steel gear pump is suitable for conveying places with strict noise requirements, high performance requirements and high volume efficiency, such as oil tanker truck transportation, test sites, medical industry, feed machinery, etc.

3. Stainless steel gear pump can transport food industry with high hygienic requirements, such as grain, oil, honey, coconut juice and other food transportation.

4. Stainless steel gear pump can be used for transportation of ship engineering, naval vessels, aviation kerosene, etc.

5. Stainless steel gear pumps can also be used in power plants, water conservancy projects, fuel oil systems, oil delivery systems, hydraulic engineering, etc. that require cautious explosion-proof environments.

SS gear pump can also transport asphalt, heavy oil, heavy oil, grease and other working conditions with relatively high viscosity and not very clean materials. For special working conditions, the over-flow material of stainless steel gear pump will be specially heat treated to enhance wear resistance. The processing precision of stainless steel gear pumps of Syken Pumps is relatively high, and it has been highly evaluated in the industry for many years. It is used in supporting domestic large-scale projects and exporting abroad.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501