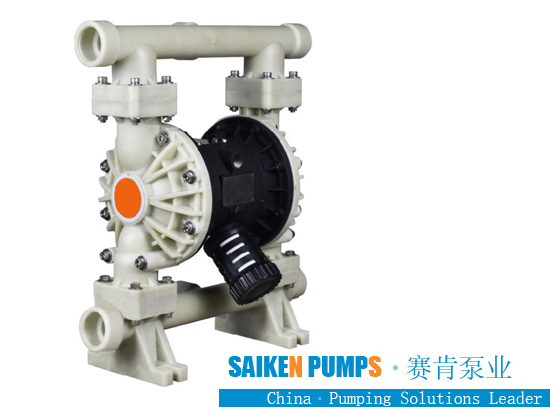

The Air Operated Double Diaphragm Pump is a double-suction diaphragm pump chamber. Of course, there are also single-chamber pneumatic diaphragm pumps, but the flow and head are definitely not as large as the double-suction diaphragm pump. The pneumatic diaphragm pump has a long service life. If the internal membrane is used If the quality of the film is good, the service life of the pneumatic diaphragm pump can reach more than 10 years. This kind of pump will not stop and never jam. It can transport not only flowing liquid media, but also difficult-to-flow media, and even dust , It has the comprehensive advantages of self-priming pump, submersible pump, mud pump, canned motor pump, etc. It can be described as a powerful diaphragm pump. It is mainly driven by compressed air and driven by general air compressors. Both liquids and liquids with particles can be pumped clean. Because it does not have a motor, it can be used safely in flammable and explosive situations. It can also be used to immerse the pump in a liquid medium. It will not damage the pump when idling. Since there are no rotating parts and shaft seals, it is a leak-proof pump.

1. No need to irrigate and divert water, suction lift up to 7m, head up to 70m, outlet pressure ≤ 0.8Mpa

2. The flow is spacious and the passing performance is good, allowing large particles up to 9.4mm in diameter. When pumping mud and impurities, there is little wear on the pump:

3. The head and flow can be adjusted by the air source pressure (the air source pressure is between 0.1-0.8Mpa);

4. Working environment range: 5-65℃; conveying medium range (-20℃-150℃);

5. The pump has no rotating parts and no shaft seal. The diaphragm completely separates the pumped medium from the moving parts and working medium of the pump, and the conveyed medium will not leak outward. Therefore, when pumping toxic, volatile and corrosive media, it will not cause environmental pollution and endanger personal safety;

6. No need for electricity, safe and reliable to use in flammable and explosive places;

7. Can be submerged in the medium to work;

8. It is convenient to use, reliable in operation, and only needs to open and close the gas valve for starting and stopping. Even if there is no medium for a long time due to unexpected conditions or sudden shutdown, the pump will not be damaged. Once overloaded, the pump will automatically stop, with self-protection performance, when the load returns to normal, it can automatically start operation.

9. Simple structure with few wearing parts. The pump structure is simple, easy to install and maintain. The medium conveyed by the pump will not come into contact with moving parts such as the pump valve, connecting rod, etc., and the performance of other types of pumps will not gradually decrease due to the wear of rotors, pistons, gears, blades and other parts;

10. It can transport more viscous liquids (viscosity below 10,000 centipoise);

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501