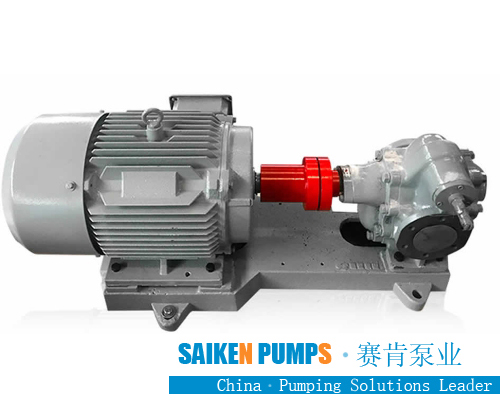

KCB stainless steel gear oil pump usage description: 1. It is suitable for conveying various oils, such as heavy oil, diesel oil, and lubricating oil. It is equipped with copper gears to convey low-point liquids, such as gas oil and stupid. This unit also produces stainless steel gear pumps that can convey beverages and corrosive liquid.

2. It is not suitable for those containing hard particles or fibers, and the applicable viscosity is 5×10-5~1.5×103m2/s. The temperature is not high at 70℃. If you need to transport high temperature liquid, please use high temperature gear pump, which can transport liquid below 300℃.

Characteristics of stainless steel magnetic pump:

KCB stainless steel gear pump is mainly composed of gears, shafts, pump bodies, safety valves, shaft end seals (magnetic drive, zero leakage structure can be selected for special requirements). The gear has a higher hardness and strength after heat treatment, and it is installed in a replaceable sleeve together with the shaft to run. The lubrication of all parts in the pump is automatically achieved by using the output medium when the pump is working.

The KCB stainless steel gear pump has reasonably designed oil drain and oil return grooves, which is the smallest torque force that the gear bears during work, so the bearing load is small, the wear is small, and the pump efficiency is high. The pump is equipped with a safety valve as overload protection. The total return pressure of the safety valve is 1.5 times the rated discharge pressure of the pump. It can also be adjusted according to actual needs within the allowable discharge pressure range. But note that this safety valve cannot be used for long-term operation of a pressure reducing valve, and can be installed separately on the pipeline when necessary.

Seen from the extension end of the main shaft to the pump, it rotates clockwise.

Whether the fasteners of the pump are firm; whether the valves of the inlet and outlet pipes are open; whether the rotation direction of the pump meets the requirements; when the high-temperature medium is transported, it should be operated for one minute before connecting.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501