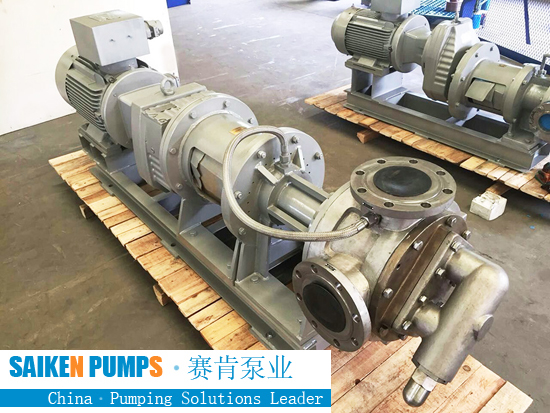

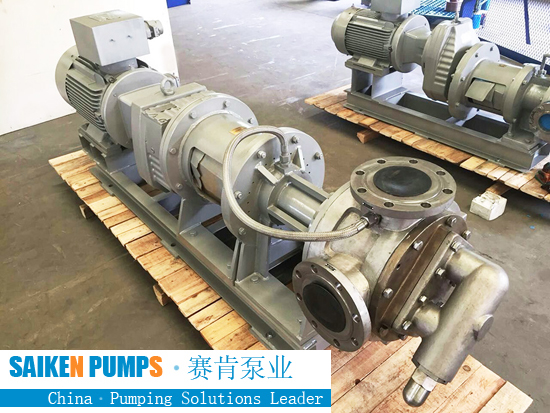

High viscosity gear pumps usually deliver medium with a relatively high viscosity. When selecting a high-viscosity gear pump, the number of revolutions of the selected gear motor must be determined according to the conveyed medium. The higher the viscosity, the higher the viscosity of the high viscosity gear pump. The lower it is, in order to ensure the normal use of the high viscosity pump. High viscosity gear pump is mainly composed of inner and outer rotor, shaft, pump body, front cover, bracket, seal, bearing and so on. There are two forms of sealing: mechanical seal and packing seal. For medium with high temperature, high viscosity and strong corrosiveness, use packing seal. For special requirements, magnetic drive can be used, zero leakage structure.

The high-viscosity gear pump is very suitable for conveying high-viscosity materials such as high-viscosity resins, polyurethanes, poly-mysters, polyethylene, asphalt mixtures, etc.; especially suitable for the conveyance of high-viscosity and consistency media; when conveying easily crystallized materials, the front cover and the pump body It can be designed with a thermal insulation jacket, which can be introduced into the jacket through various heat media such as hot steam, thermal oil, etc. during operation. The high-viscosity gear pump can be equipped with a safety valve. When the high-viscosity gear pump or pipeline system is overpressured, the safety valve opens to form an internal backflow to ensure the safety of the system.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501