1. Performance characteristics

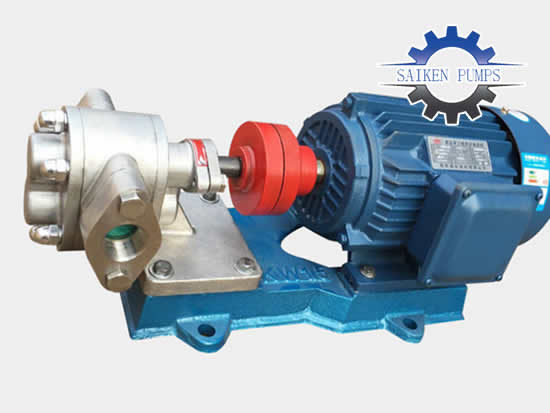

The gear pump adopts involute gears or arc gears. Generally have a safety valve. Gear oil pump is suitable for conveying lubricating and non-corrosive oils and other liquid media, and suitable for conveying high-lift media. The gear oil pump is lubricated by the conveyed medium. The advantage is that the medium is not demanding. The general pressure does not exceed 6MPa. It has the characteristics of self-priming, uniform flow and reliable operation.

2. Working principle

The gear pump is a positive displacement rotary pump. The work is accomplished by installing two gears of the same size in the casing to mesh and rotate. One driving wheel and one driven wheel. The two ends of the gear are sealed by the front and rear covers. The gear divides the inside of the pump casing into two. There are two independent working chambers, namely the suction chamber and the discharge chamber. The driving gear of the gear oil pump drives the driven gear to rotate during delivery. When the gear is disengaged, the volume of the chamber gradually increases. A partial vacuum is formed in the suction chamber, and the liquid is sucked in. The liquid fills the teeth of the gear and is brought to the discharge cavity. When the gear enters the mesh, the volume gradually decreases to form a high-pressure liquid and discharge it out of the pump through the pump discharge port. According to the continuous rotation and meshing of the gears, the liquid is continuously discharged to complete the conveying work.

3. The scope of use

Gear pumps are widely used in petroleum, chemical, shipbuilding, electric power, grain and oil, food, medical, building materials, metallurgy and other industries. Gear oil pumps are not suitable for conveying solid particles, fibers, and corrosive media. They are suitable for conveying lubricating oil with a temperature below 180°C and a viscosity between 5 and 1500 cst or other liquids with similar properties. It is suitable for all kinds of occasions where heat preservation is required in the process of outdoor installation in alpine areas with solidification at room temperature. Gear oil pumps are relatively cost-effective.

Gear pump manufacturers and suppliers from China

Gear pump manufacturers and suppliers from China

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501