The air diaphragm pump uses compressed air as the power source. It is a positive displacement pump whose volume changes due to the reciprocating deformation of the diaphragm. Its working principle is similar to that of a plunger pump. The pneumatic diaphragm pump has four materials: engineering plastics, aluminum alloy, cast iron, and stainless steel. The pneumatic diaphragm pump adopts nitrile rubber, neoprene rubber, fluorine rubber, polytetrafluoroethylene, polyhexaethylene according to different liquid media.

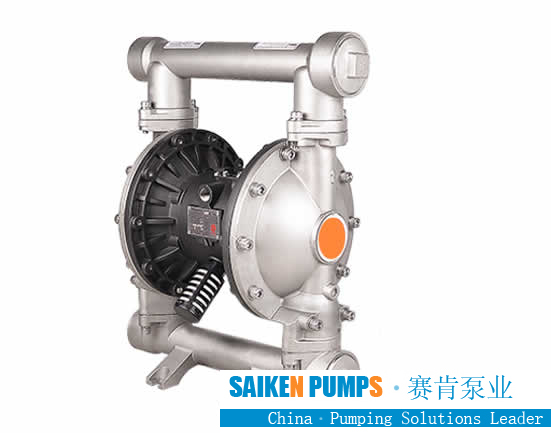

Pneumatic single diaphragm pump

2. Features of pneumatic single diaphragm pump:

(1) The pump will not overheat and no harmful gas will be discharged.

(2) It will not produce electric sparks, is not easy to be blocked, and has little agitation to materials, which is suitable for the transportation of unstable substances.

(3) The pump can always maintain high efficiency, will not be reduced due to wear, and can transport a wide range of fluids, from low viscosity to high viscosity, and viscous from corrosiveness.

(4) There is no dynamic seal, easy maintenance to avoid leakage. There is no dead point when working, 100% energy utilization, when the outlet is closed, the pump automatically stops.

(5) The flow can be adjusted, and a throttle valve can be installed at the material outlet to adjust the flow.

(6) It has the function of self-priming.

(7) It can run dry without danger.

(8) Can dive for work.

(9) There is no need for lubrication, so it is easy to maintain and will not pollute the working environment due to dripping.

(10) No complicated control system, no cables, fuses, etc.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501