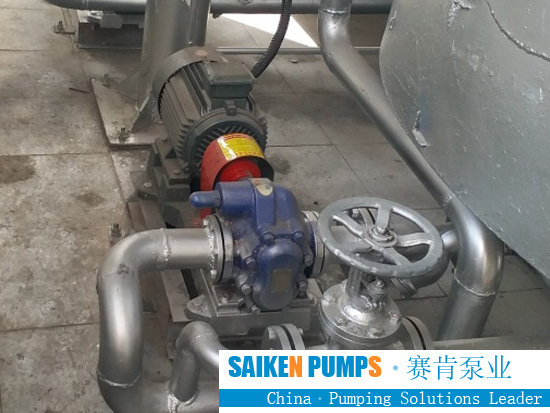

The working point of the stainless steel gear pump is determined by the characteristic curve of the pump and the characteristic curve of the piping system together. Therefore, changing any characteristic curve can achieve the purpose of flow regulation. At present, the flow adjustment methods of stainless steel gear oil pumps mainly include regulating valve control, variable speed control, and pump parallel and series adjustment.

1. Change the pipeline characteristic curve of SUS gear pump

The simple way to change the flow rate of a stainless steel gear pump is to use the opening of the pump outlet valve to control. The essence is to change the position of the pipeline characteristic curve to change the pump's working point.

2. Change the characteristic curve of stainless steel gear pump

According to the law of proportionality and the law of cutting, changing the speed of the stainless steel gear pump and changing the pump structure can change the characteristic curve of the stainless steel gear pump, so as to achieve the purpose of adjusting the flow rate (at the same time changing the pressure head).

Third, the series and parallel adjustment methods of stainless steel gear pumps

When a single stainless steel gear pump cannot meet the delivery task, parallel or series operation of stainless steel gear pumps can be used. Using two stainless steel gear pumps of the same model in parallel, although the pressure head changes little, the total delivery flow is increased. The total efficiency of the parallel pumps is the same as that of a single pump; when the stainless steel gear pumps are connected in series, the total pressure head increases The total efficiency of the series pump is the same as that of a single pump.

Manufacturer and manufacturer of oil pumps in China

Manufacturer and manufacturer of oil pumps in China

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501