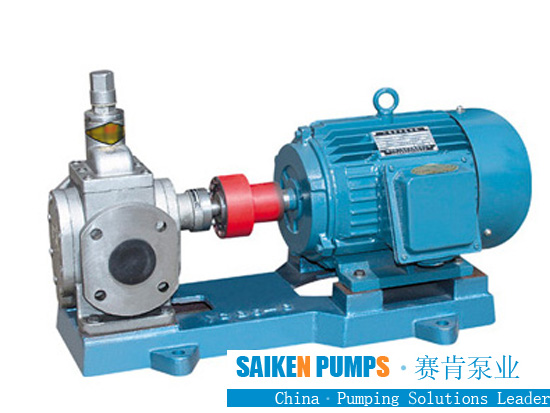

Stainless steel gear pumps often have short service life and fast wear of gears and thrust plates during use. Especially when transporting non-lubricated or poorly lubricated media, the gears of the gear pump will wear quickly and have good sealing. Leakage, the actual product and working conditions were analyzed by our company's technicians and the problem was finally found out.

The main reason is that the choice of stainless steel gear pump is because you don’t know enough about the medium that the pump delivers, and the material selection of the pump is not accurate enough. Conventional SUS gear pumps generally use 304 stainless steel for the pump body and 304 stainless steel or 2Cr13 for the gear. For heat treatment or nitriding treatment, most bearings are made of stainless steel bushings and steel backed composite sleeves, and 23Cr13 is mostly used for spindles. Actually, this combination of materials is perfectly suitable for conveying lubricating media, but if it is used for conveying impurities or no For media with poor lubricity and lubricity, the hardness of the material is not large enough, and the wear resistance and fatigue resistance of the material are poor. When the gear pump is concentric with the motor, the gear wear is slightly slower. If the gear pump and the motor are concentric If the temperature is slightly lower, each component of the gear pump will wear very quickly. Once the shaft sleeves and gears of the gear pump are worn, the shaft will be bounced and sealed to cause leakage.

In addition, stainless steel gear pumps generally transport more acid and alkali media, which often have very low viscosity. Due to the large thermal expansion coefficient of 304 stainless steel, the general manufacturer considers that the temperature rise will easily cause the gear pump to lock and shaft when assembling the stainless steel gear pump. Therefore, the gap will generally be offset when assembling the stainless steel gear pump. Bigger. Due to the low viscosity of the conveying medium, the large internal clearance of the pump will cause the phenomenon that the stainless steel gear pump does not suck or the flow and head are insufficient.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501