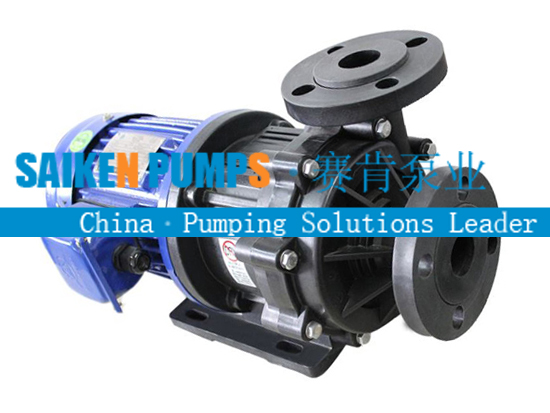

The magnetic drive pump produced by Seken Pump is designed to prevent leakage without shaft seal. Electroplating, painting, waste gas, waste water, etching, PCB circuit board and other industries.

Small magnetic pump:

Let me introduce the working principle and advantages of magnetic drive pump

The working principle of the magnetic drive pump: the magnetic drive pump (magnetic drive pump) is mainly composed of pump head, magnetic drive (magnetic cylinder), motor, connecting main shaft and other parts. The inner magnetic rotor and non-magnetic isolation sleeve are composed when the motor drives When the outer magnetic rotor rotates, the magnetic field can penetrate the air gap and non-magnetic material, and drive the inner magnetic rotor connected with the impeller to rotate synchronously, realizing the contactless and synchronous power passing through the pump shaft. The inner magnetic rotor is completely enclosed by the pump body and the isolation sleeve. , Thereby solving the problem of "running, emitting, dripping and leaking".

Advantages of magnetic drive pump:

(1) Since the transmission shaft does not need to penetrate the pump casing, or use the magnetic field to penetrate the air gap and the thin-walled transmission diaphragm of the isolation sleeve to drive the inner rotor, the leakage passage of the shaft seal is eliminated and the seal is realized.

(2) Overload protection function when transmitting power.

(3) Except for the higher requirements for magnetic materials and magnetic circuit design, the remaining technical requirements are relatively low.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501