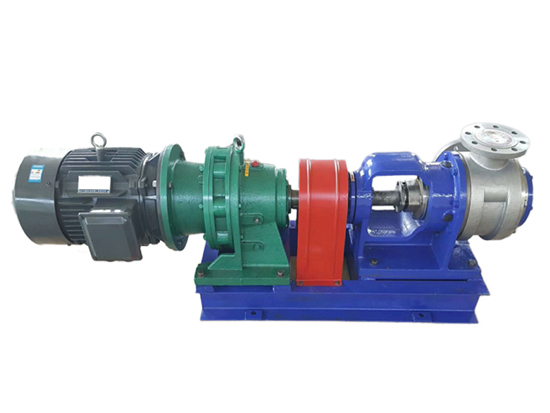

High viscosity pump maintenance precautions:

High-viscosity rotor pumps have good mechanical properties, and the wearing parts of high-viscosity pumps should be well maintained and operated according to the instruction manual of the high-viscosity pump. High-viscosity rotor pump parts are pushed and protected. High-viscosity pumps should be stored and disassembled during the process of disassembly. Please follow the steps to install carefully. Small problems during installation may cause large problems of high-viscosity rotor pumps.

The location of the high-viscosity rotor pump is very particular. The location should be protected from moisture and moisture. If it is a high-viscosity rotor pump made of cast iron, it is easy to rust in this environment for a long time. The motor of the high-viscosity rotor pump should be configured reasonably , Every high-viscosity rotary pump has a matching motor, and there can be no "big horse-drawn trolley" or "small horse-drawn trolley" phenomenon. Both of these are undesirable and easily lead to high viscosity. damage.

The high-viscosity rotor pump must maintain its lubricity during operation, and the grease is easy to volatilize. Grease should be added regularly to ensure the lubrication and cleanliness of the bearings and ensure the good operation of the high-viscosity rotor pump.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501