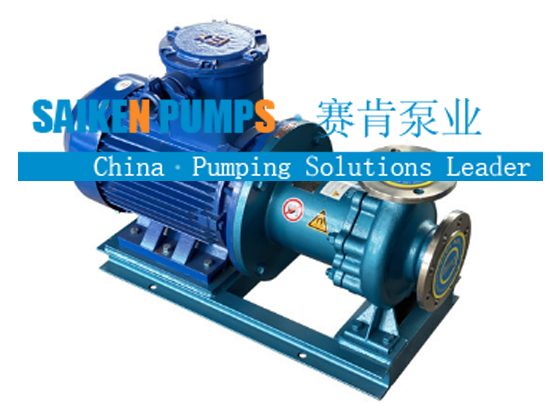

Common sense and working conditions of stainless steel magnetic drive pump

Stainless steel magnetic pump is suitable for transporting low viscosity, non-flammable, explosive and easy to vaporize. It is widely used in high-rise building water supply and drainage plant filtration and transportation, pipeline pressurization, etc.; flushing and cleaning system, water treatment system and other equipment supporting systems; ultrafiltration system , Reverse osmosis system, distillation system, separator, swimming pool and other water treatment environments.

Device specifications and precautions for use of stainless steel magnetic pump: Magnetic drive can be divided into synchronous or asynchronous design. Most stainless steel magnetic pumps use synchronous designs. The motor is connected with the outer magnet through an external coupling, and the impeller is connected with the inner magnet. There is a fully sealed barrier sleeve between the outer magnet and the inner magnet, which completely separates the inner and outer magnets, so that the inner magnet is in the medium, and the rotor shaft of the motor directly drives the impeller to synchronize through the attraction of the magnetic poles between the magnets. scroll.

1. Check whether the rotation direction of the motor is consistent with the steering symbol of the stainless steel magnetic pump.

2. Before the pump stops working, the sweep valve should be closed first, and then the suction pipe door should be closed.

3. The stainless steel magnetic pump should be installed horizontally and not erected. For occasions with special requirements for vertical installation, the motor must face upwards.

4. The stainless steel magnetic drive pump should be checked before use. The motor blades should be sensitive to rolling, without jamming or abnormal noise, and all fasteners should be tightened.

Inverter selection only needs to consider the load power. Many users usually only match the inverter capacity based on the power of the driving motor when purchasing inverters. If the comprehensive factors are not fully considered, the inverter may be damaged due to improper use. Equipping with necessary braking units and filters may cause safety risks.

1. Uneven load: Some loads are sometimes light and sometimes heavy. At this moment, the inverter capacity should be selected according to the heavy load conditions, such as rolling mill machinery, destruction machinery, mixers, etc.

2. Large inertial loads: such as centrifuges, punch presses, and rotary kilns in cement plants. When the motor decelerates, there is energy feedback. A frequency converter with a larger capacity should be used to accelerate the start to prevent oscillation.

3.The characteristic of the load is that the impact is great when starting, so a certain margin of the inverter is required. At the same time, put the elbow under the heavy object, so use the brake unit or use the shared bus method.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501