(1) Check the temperature rise of the pump and motor frequently. The temperature rise of the bearing should not be greater than 150°C, and the limit temperature should not be greater than 250°C.

(2) Pay attention to the change of the oil storage level of the suspension body, and always control it within the specified range. In order to keep the oil clean and good lubrication, the new oil should be replaced regularly according to the actual situation on site. Under normal circumstances, after every 1500 hours of operation, the new oil must be replaced.

(3) During operation, if abnormal sounds or other faults are found, stop and check immediately, and then continue to operate after the fault is eliminated.

(4) Never allow the gate valve on the suction pipeline to adjust the flow rate to avoid cavitation.

(5) The external lubrication gear pump should not be operated continuously under 30% of the design flow. If it must be operated continuously under this condition, a bypass channel should be installed at the outlet to discharge excess flow.

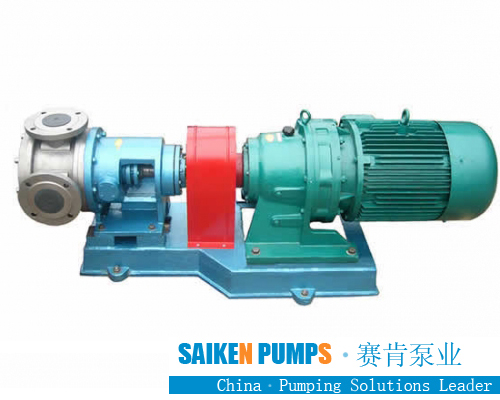

Gear pump manufacturers and suppliers from China

Gear pump manufacturers and suppliers from China

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501