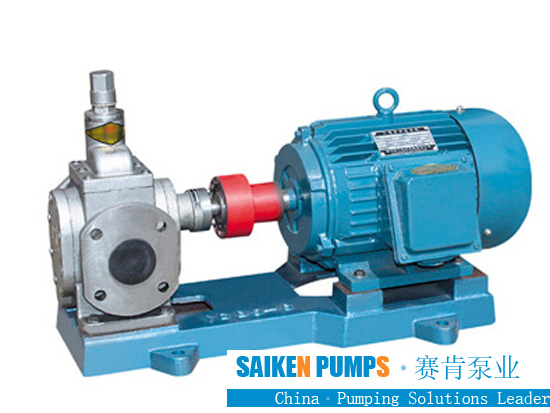

The stainless steel gear pump has a simple and compact structure, and is convenient to use and maintain. The lubrication of the stainless steel gear pump is automatically achieved by the conveyed liquid, so there is no need to add lubricating fluid during daily work.

Stainless steel gear pump characteristics

1.The stainless steel gear pump has a simple and compact structure, and is easy to use and maintain.

2.Stainless steel gear pump is self-priming, so it is not necessary to fill in liquid before starting the pump.

3. The lubrication of the stainless steel gear pump is automatically achieved by the conveyed liquid, so there is no need to add lubricating liquid during daily work.

4. The use of elastic coupling to transmit power can compensate for small deviations caused by installation. When the pump is subjected to inevitable hydraulic shocks, it can play a buffering role.

Stainless steel gear pump structure

l, Stainless steel gear pump is a horizontal rotary pump, mainly composed of pump body, gear, bearing seat, valve, bearing and sealing device.

2. The pump body, bearing seat, etc. are made of gray cast iron, and the gears are made of carbon steel, and can also be made of copper or stainless steel according to the special needs of users

3. There is a stuffing box chamber on the bearing seat, which acts as an axial seal. KCB-300~960 type pump adopts mechanical tight device, and the bearing adopts single row radial ball bearing. KCB-18.3.~83.3 type pump adopts three oil-resistant rubber It is composed of a retaining ring between the ring and the intermediate lining. The two nuts on the compression cover are adjusted to adjust the degree of sealing. The bearing adopts copper-based powder oil-impregnated bearings. In addition, stainless steel gear pumps can be sealed with packing for good elasticity and high temperature resistance And low temperature, chemically stable and flexible graphite with self-lubricating properties as filler.

4. The stainless steel gear pump is equipped with a valve. When the pump or discharge pipeline fails or the discharge valve is closed by mistake, the valve will automatically open when a high pressure and high pressure shock occurs, and part or all of the high pressure liquid is removed and returned to the low pressure chamber. It protects pumps and pipelines.

5.Use an elastic coupling to directly connect with the drive motor and install it on a common cast iron chassis.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501