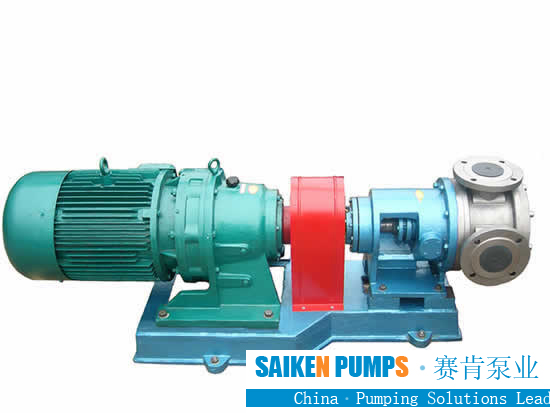

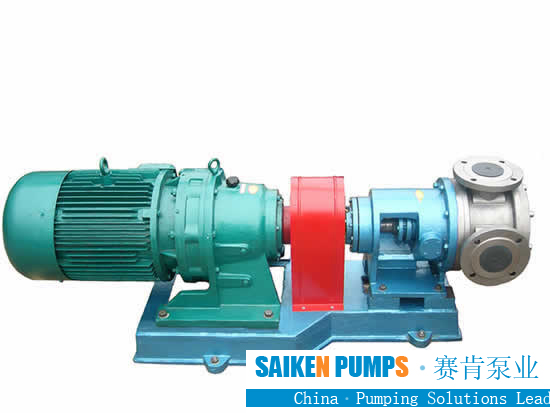

Gear pumps are classified into internal gearing and external gearing according to the meshing classification. General KCB, YCB, 2CY and other models are external gear pumps. Internal gear pumps are NYP internal gear pumps. So what are its advantages?

NYP internal gear pump is a new type of positive displacement pump developed according to the needs of the industry. Because the product can choose different materials and its unique structure, it is widely used in media with different properties and different viscosities. The pump conveys liquid smoothly, without pulsation, small vibration, low noise and strong self-priming performance. The correct selection of parts and materials can transport a variety of corrosive media, and the use temperature can be 200 ℃. The rotation of the inner and outer rotors is the same, with little wear and long service life. The speed of the pump and the flow rate are linear functions, and the number of rotations can be appropriately changed to change the flow rate of the pump. It is especially suitable for the transportation of high viscosity and consistency medium.

When customers come to inquire about internal gear pumps, they must understand the following conditions in detail during the communication process:

1. Flow rate is one of the important performance data of gear oil pump selection, it is directly related to the production capacity and delivery capacity of the entire device. Usually based on the large flow rate, taking into account the normal flow rate. When there is no large flow rate, usually 1.1 times the normal flow rate can be taken as the large flow rate. Generally, industrial pumps can ignore the leakage in the piping system in the process, but the impact on the flow rate when the process changes must be considered.

2. The viscosity of the material conveyed by the NYP high-viscosity rotor pump is directly related to the number of revolutions of the pump.

3. The piping arrangement conditions of the NYP high-viscosity rotor pump device system refer to the distance, height, and direction of the liquid. In order to facilitate pressure calculation and power inspection, piping system data (pipe diameter, length, type and number of pipeline accessories, geometric elevation from oil suction pool to pressure oil pool, etc.).

4. Liquid properties, including the name of the liquid medium, physical properties, chemical properties and other properties. The physical properties include temperature c, density d, viscosity u, solid particle diameter and gas content in the medium, etc., which involve the pressure of the system and require Power calculation and suitable pump type: chemical properties, mainly refer to the chemical corrosiveness and toxicity of the liquid medium, which is an important basis for selecting gear oil pump materials and selecting which type of shaft seal.

5. The pressure required by the device system is another important performance data for selecting gear oil pumps. Generally, the pressure after amplifying 5%-10% of the margin is used to select the type of cycloid gear pump. This includes: suction sump pressure, discharge sump pressure, pressure drop (pressure loss) in the piping system.

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501